| |

| Products |

|

Category List |

|

|

|

|

| | |

|

|

|

| |

|

| |

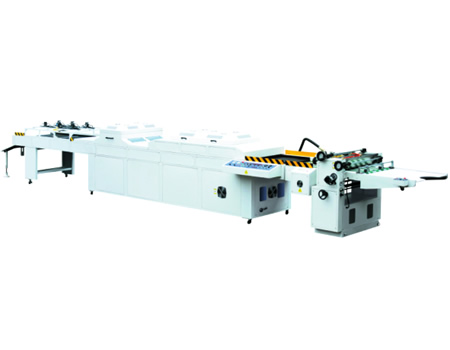

(Lengthen)

Main construction features:

1,、Apply three rolls coating method.

2,、The scraping knife use imported unit with hydraulic structure.

3、Casting iron machine body with high precision and not easy to deformation.

4,、Chain running device ensure stable running.

5,、The uniform coating effect and fine adjustment system make the surface of paper more smooth.

6,、The coating oild is thinner and more uniform. It can eliminate the pin hole and orange skin phonomenom.

7,、The scraping knife is more trim and can remore the UV oil slicking to the surface of impression cylinder to avoid the back of paper from dirty.

Main Specification:

| Model |

SGC720 |

SGC1000 |

SGC1200 |

| Max.Width |

720mm |

950mm |

1150mm |

| Paper used |

200-600mm² |

200-600mm² |

200-600mm² |

| Speed |

0-60m/min |

0-60m/min |

0-60m/min |

| Overall Dimensions |

9000×1300×1600mm |

9000×1600×1600mm |

9000×1800×1600mm |

| Oberall weight |

1.8T |

2.5T |

3T |

| Total Power |

43kw |

50kw |

50kw |

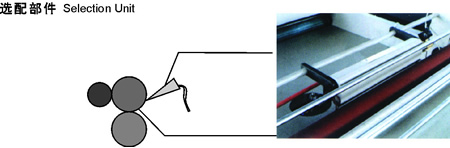

Air-knife Unit:

In order to coating thin paper, our company studied and developed a new technology, Air-knife Unit, which has achieved national patent. By equi-pping with coating machine, the range of paper could extent to 100g-600g. It use special tuyere device and air dropping technology, which overcome some disadvantage of the similar products manufactured byother factory in domestic and overseas. Its property is stable and reliabe, easy regulation. So it is an idea prodects for thin-paper coating. |

| 【Close】 |

|

|

| | |

|